Discover the superior performance of carbide-tipped band saw blades by Eberle. Engineered for precision and durability, these blades enhance efficiency in industrial applications. Carbide-tipped band saw blades are a game-changer in the world of cutting tools. These blades are designed to offer superior performance, precision, and durability. Discover the precision and durability of Eberle Carbide-Tipped Band Saw Blades , designed for cutting tough materials with ease. Enhance productivity with our expert insights on features, benefits, and maintenance tips.. They are particularly popular in industrial applications where efficiency and accuracy are paramount. Eberle, a renowned name in the industry, has been at the forefront of developing high-quality band saw blades that cater to a wide range of cutting needs. Their carbide-tipped blades are known for their exceptional cutting precision and long-lasting performance. This post delves into the various aspects of carbide-tipped band saw blades, highlighting their benefits, applications, and maintenance tips. Whether you're in manufacturing, construction, or any other industry that requires precise cutting, understanding the advantages of these blades can significantly enhance your operations. Let's explore how carbide-tipped band saw blades can transform your cutting processes and why Eberle is a trusted choice for professionals worldwide.

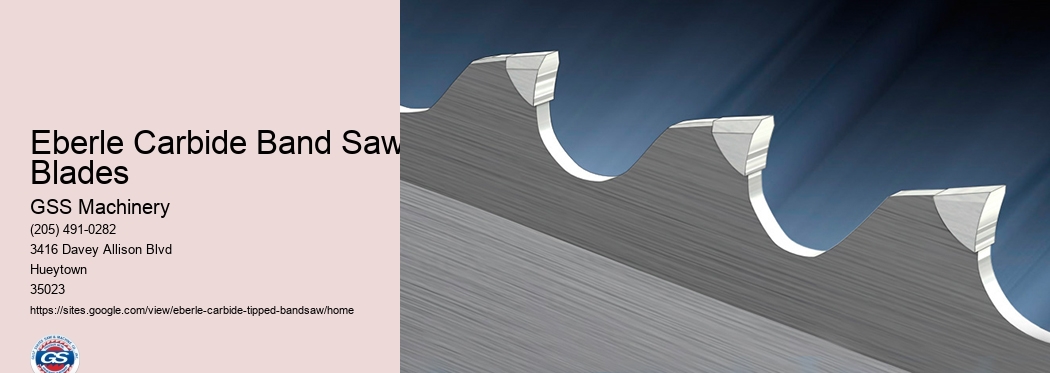

Carbide-tipped band saw blades are engineered for precision. The carbide tips are incredibly hard, allowing them to maintain a sharp edge longer than traditional blades. This sharpness is crucial for achieving clean, accurate cuts. Eberle carbide saw blades The design of these blades minimizes vibration during cutting, which is a common cause of imprecision. Less vibration means smoother cuts and less material waste. The teeth of carbide-tipped blades are also designed to reduce friction. This results in less heat generation, which can distort materials and affect precision. The consistent tooth geometry ensures uniform cutting performance across various materials. Additionally, carbide-tipped blades can handle higher cutting speeds. This capability not only improves efficiency but also enhances precision by reducing the chances of blade deflection. The combination of these features makes carbide-tipped band saw blades an excellent choice for applications requiring high precision. They are ideal for cutting metals, plastics, and other challenging materials where accuracy is critical. By choosing carbide-tipped blades, you ensure that your cuts are precise, reducing the need for secondary processing and saving time and resources.

Eberle band saw blades are synonymous with quality and reliability. In industrial applications, where downtime can be costly, Eberle blades offer unmatched performance. One of the primary benefits is their durability. Eberle blades are designed to withstand the rigors of continuous use, reducing the frequency of blade changes. This durability translates to cost savings over time. Another advantage is their versatility. Eberle offers a range of blades suitable for different materials and cutting requirements. Whether you're cutting steel, aluminum, or wood, there's an Eberle blade designed for the task. The precision of Eberle blades is another significant benefit. Their consistent performance ensures that cuts are accurate, reducing material waste and improving product quality. Eberle's commitment to innovation means their blades incorporate the latest technology, enhancing cutting efficiency and safety. The ease of maintenance is also a plus. Eberle blades are designed for easy cleaning and sharpening, extending their lifespan. In summary, Eberle band saw blades provide industrial users with a reliable, cost-effective solution that enhances productivity and product quality.

Carbide-tipped band saw blades are incredibly versatile. They can cut a wide range of materials with ease. Metals are a primary application. These blades can handle everything from soft metals like aluminum to hard metals like stainless steel and titanium. The hardness of the carbide tips allows them to cut through tough materials without losing sharpness. Plastics are another material that can be efficiently cut with carbide-tipped blades. Whether it's acrylic, PVC, or polycarbonate, these blades provide clean, precise cuts. Wood is also on the list. Carbide-tipped blades are excellent for cutting hardwoods and engineered wood products. They maintain their sharpness longer than traditional blades, making them ideal for high-volume wood cutting. Composites, which can be challenging to cut due to their mixed material composition, are also suitable for carbide-tipped blades. The blades' ability to maintain precision and reduce heat generation makes them perfect for cutting these complex materials. In essence, carbide-tipped band saw blades are a versatile tool that can handle a wide array of cutting tasks, making them invaluable in various industries.

When it comes to durability, carbide-tipped band saw blades have a clear advantage over traditional blades. The carbide tips are significantly harder than the steel used in conventional blades. This hardness allows them to maintain their cutting edge for a longer period. Traditional blades tend to dull quickly, especially when cutting hard materials. This leads to frequent blade changes and increased downtime. In contrast, carbide-tipped blades can withstand the demands of cutting tough materials without losing sharpness. The longevity of carbide-tipped blades translates to cost savings. Fewer blade changes mean less time spent on maintenance and more time on production. Additionally, the durability of carbide-tipped blades reduces the risk of blade breakage. This enhances safety and minimizes the risk of damage to the workpiece. While carbide-tipped blades may have a higher upfront cost, their extended lifespan and superior performance make them a cost-effective choice in the long run. For industries where cutting efficiency and reliability are crucial, carbide-tipped band saw blades offer unmatched durability and performance.

Proper maintenance is key to extending the life of Eberle band saw blades. Regular cleaning is essential. After each use, remove any debris or residue from the blade. This prevents buildup that can affect performance. Sharpening is another critical aspect. Keep the blade sharp to ensure clean cuts and reduce strain on the blade. Use a sharpening tool designed for band saw blades to maintain the correct tooth geometry. Tension is also important. Ensure the blade is properly tensioned before use. Incorrect tension can lead to blade deflection and uneven cuts. Lubrication is beneficial, especially when cutting metals. Carbide tipped band saws Use a suitable lubricant to reduce friction and heat generation. High-performance band saws This helps maintain the blade's sharpness and prevents warping. Storage is often overlooked. Store blades in a dry, cool place to prevent rust and corrosion. Avoid stacking blades to prevent damage. By following these maintenance tips, you can significantly extend the life of your Eberle band saw blades, ensuring they deliver optimal performance for longer.

Eberle carbide-tipped band saw blades are packed with features that enhance their performance. The carbide tips are the standout feature. They provide exceptional hardness and wear resistance, ensuring the blades remain sharp for longer. This results in precise cuts and reduced downtime for blade changes. The tooth geometry of Eberle blades is meticulously designed. It minimizes vibration and heat generation, which are common issues in cutting applications. This design ensures smoother cuts and prolongs blade life. Eberle blades are also known for their versatility. They can cut a wide range of materials, from metals to plastics and wood. This versatility makes them a valuable tool in various industries. The blades are engineered for high-speed cutting, enhancing efficiency and productivity. Eberle's commitment to quality means their blades undergo rigorous testing to ensure they meet the highest standards. This reliability is why professionals trust Eberle blades for their critical cutting tasks. In summary, the key features of Eberle carbide-tipped band saw blades make them a top choice for those seeking precision, durability, and versatility.

Selecting the right band saw blade is crucial for achieving optimal cutting results. The first consideration is the material you need to cut. Different materials require different blade types. For metals, a carbide-tipped blade is often the best choice due to its hardness and durability. For wood, a blade with a larger tooth pitch may be more suitable. The thickness of the material is another factor. Thicker materials may require a blade with a wider kerf to ensure stability during cutting. The desired finish is also important. If a smooth finish is required, a blade with a finer tooth pitch may be necessary. Cutting speed is another consideration. High-speed cutting requires blades designed to withstand the increased friction and heat. Finally, consider the machine's specifications. Ensure the blade is compatible with your band saw's size and power. By taking these factors into account, you can choose the right band saw blade for your specific cutting needs, ensuring efficiency and precision in your operations.

Carbide-tipped band saw blades, while highly efficient, can encounter issues. One common problem is blade dulling. This can occur if the blade is used on materials it wasn't designed for. Regular sharpening can mitigate this issue. Another issue is blade breakage. This can result from incorrect tension or excessive feed pressure. Ensure the blade is properly tensioned and adjust the feed rate to prevent breakage. Vibration is another concern. It can lead to imprecise cuts and increased wear. Check the blade alignment and ensure the machine is stable to reduce vibration. Heat buildup is also a problem. It can cause the blade to warp or lose its temper. Use a suitable lubricant to reduce friction and heat generation. Lastly, material sticking to the blade can affect performance. Regular cleaning can prevent this issue. By addressing these common problems, you can ensure your carbide-tipped band saw blades perform optimally and have a longer lifespan.

Eberle blades are designed to enhance cutting efficiency in manufacturing. Their precision-engineered tooth geometry ensures clean, accurate cuts, reducing material waste. This precision is crucial in manufacturing, where even minor inaccuracies can lead to significant losses. The durability of Eberle blades means they require less frequent changes. This reduces downtime and increases productivity. The high-speed cutting capability of Eberle blades further enhances efficiency. They can handle demanding cutting tasks quickly, allowing for faster production cycles. Eberle's commitment to quality ensures their blades maintain performance even under continuous use.

Eberle is at the forefront of band saw blade technology. Their innovations have set new standards in the industry. One of their key advancements is in carbide-tipped blade technology. Eberle has developed blades with enhanced carbide formulations, providing superior hardness and wear resistance. Carbide tipped blades This innovation extends blade life and improves cutting performance. Eberle has also focused on improving tooth geometry. Their blades feature designs that minimize vibration and heat generation, resulting in smoother cuts and longer blade life. Another area of innovation is in blade coatings. Eberle offers blades with advanced coatings that reduce friction and enhance durability. These coatings also improve cutting efficiency by allowing higher speeds. Eberle's commitment to sustainability is evident in their manufacturing processes. They use eco-friendly materials and processes to reduce their environmental impact. This focus on sustainability is an important innovation in today's industry. In conclusion, Eberle's innovations in band saw blade technology have positioned them as a leader in the field, providing cutting-edge solutions for professionals worldwide.

Carbide-tipped band saw blades are a vital tool in various industries. Their precision, durability, and versatility make them indispensable. Eberle stands out with its innovative approach and commitment to quality. Their blades offer unmatched performance, enhancing efficiency and productivity. By understanding the benefits and maintenance of these blades, you can optimize your cutting operations. Whether you're in manufacturing, construction, or any other field, choosing the right blade is crucial. Eberle provides reliable solutions that meet diverse cutting needs. Their continuous advancements ensure they remain a leader in band saw blade technology. Investing in Eberle blades means investing in quality and efficiency.

Gulf States Saw & Machine Co.

Manufacturer in Hueytown, Alabama

Directions

Located in: Alabama Tool & Supply Co

Address: 3416 Davey Allison Blvd, Hueytown, AL 35023, United States

Phone: +1 205-491-0282

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Entity | Description | Link |

| Eberle band saw blades | Eberle is a company specializing in the production of industrial saw blades, including band saw blades. | Eberle Wikipedia |

| Carbide tipped blades | Saw blades with cutting edges made from carbide, a hard material used for cutting metals and other materials. | Carbide Wikipedia |

| Eberle carbide saw blades | Specific type of saw blades produced by Eberle, using carbide tips for enhanced cutting capabilities. | Eberle Wikipedia |

| Metal cutting saw blades | Saw blades designed for cutting various types of metal, typically featuring hardened materials like carbide. | Metalworking Wikipedia |

| Carbide tipped band saws | Band saws equipped with blades that have carbide-tipped teeth for increased durability in cutting hard materials. | Bandsaw Wikipedia |

| Precision cutting blades | High-quality saw blades engineered for accurate and fine cutting applications. | Saw Wikipedia |

| Industrial band saw blades | Band saw blades used in industrial applications for cutting materials such as metals, plastics, and wood. | Bandsaw Wikipedia |

| Saw blade manufacturing | The process of creating saw blades for various cutting applications, involving material selection and precision engineering. | |

| High-performance band saws | Advanced band saw machines designed for high efficiency and precision in industrial cutting tasks. | Bandsaw Wikipedia |

| Eberle carbide cutting tools | Carbide-tipped cutting tools manufactured by Eberle, commonly used in metalworking industries. | Eberle Wikipedia |

| Carbide blade technology | Technology involving the use of carbide materials in blade manufacturing for improved cutting performance. | |

| Eberle saw blade distributor | Companies or agents who distribute Eberle brand saw blades to various industries. | |

| Band saw blade suppliers | Companies that supply different types of band saw blades for industrial and commercial uses. | Industrial supply Wikipedia |

| Carbide teeth blades | Saw blades with teeth made from or tipped with carbide, known for their hardness and wear resistance. | |

| Wear-resistant saw blades | Blades designed to resist wear and maintain sharpness longer when cutting hard or abrasive materials. | Abrasion Wikipedia |

| Advanced cutting tools | Tools used for precise and efficient cutting, often featuring materials like carbide for improved durability. | Cutting tool Wikipedia |

| Eberle blade technology | The technology and engineering behind Eberle's development of cutting-edge saw blades and cutting tools. | Eberle Wikipedia |

| Band saw blade maintenance | The practice of caring for and maintaining band saw blades to ensure optimal cutting performance. | |

| Metalworking tools | Tools specifically designed for shaping, cutting, and forming metals in various industrial applications. | |

| Carbide saw blade sharpening | The process of sharpening carbide-tipped saw blades to restore their cutting edge. | Sharpening Wikipedia |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gulf States Saw & Machine Co.

Manufacturer in Hueytown, Alabama

Directions

Located in: Alabama Tool & Supply Co

Address: 3416 Davey Allison Blvd, Hueytown, AL 35023, United States

Phone: +1 205-491-0282

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gulf States Saw & Machine Co.

3416 Davey Allison Blvd, Hueytown, AL 35023, United States

(205) 491-0282

92 languages

Tools

Appearance hide

Text

Width

Color (beta)

From Wikipedia, the free encyclopedia

For the functional constituency in Hong Kong, see Manufacturing (constituency).

Manufacturing of an automobile by Tesla

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the secondary sector of the economy.[1][unreliable source?] The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers).

Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed into a final product. The manufacturing process begins with the product design, and materials specification. These materials are then modified through manufacturing to become the desired product.

Contemporary manufacturing encompasses all intermediary stages involved in producing and integrating components of a product. Some industries, such as semiconductor and steel manufacturers, use the term fabrication instead.[2]

The manufacturing sector is closely connected with the engineering and industrial design industries.

Etymology[edit]

The Modern English word manufacture is likely derived from the Middle French manufacture ("process of making") which itself originates from the Classical Latin manū ("hand") and Middle French facture ("making"). Alternatively, the English word may have been independently formed from the earlier English manufacture ("made by human hands") and fracture.[3] Its earliest usage in the English language was recorded in the mid-16th century to refer to the making of products by hand.[4][5]

History and development[edit]

Prehistory and ancient history[edit]

See also: Industry (archaeology), Prehistoric technology, and Ancient technology

Flint stone core for making blades in Negev, Israel, c. 40000 BP

A late Bronze Age sword or dagger blade now on display at the National Archaeological Museum in France

Human ancestors manufactured objects using stone and other tools long before the emergence of Homo sapiens about 200,000 years ago.[6] The earliest methods of stone tool making, known as the Oldowan "industry", date back to at least 2.3 million years ago,[7] with the earliest direct evidence of tool usage found in Ethiopia within the Great Rift Valley, dating back to 2.5 million years ago.[8] To manufacture a stone tool, a "core" of hard stone with specific flaking properties (such as flint) was struck with a hammerstone. This flaking produced sharp edges that could be used as tools, primarily in the form of choppers or scrapers.[9] These tools greatly aided the early humans in their hunter-gatherer lifestyle to form other tools out of softer materials such as bone and wood.[10] The Middle Paleolithic, approximately 300,000 years ago, saw the introduction of the prepared-core technique, where multiple blades could be rapidly formed from a single core stone.[9] Pressure flaking, in which a wood, bone, or antler punch could be used to shape a stone very finely was developed during the Upper Paleolithic, beginning approximately 40,000 years ago.[11] During the Neolithic period, polished stone tools were manufactured from a variety of hard rocks such as flint, jade, jadeite, and greenstone. The polished axes were used alongside other stone tools including projectiles, knives, and scrapers, as well as tools manufactured from organic materials such as wood, bone, and antler.[12]

Copper smelting is believed to have originated when the technology of pottery kiln allowed sufficiently high temperatures.[13] The concentration of various elements such as arsenic increase with depth in copper ore deposits and smelting of these ores yields arsenical bronze, which can be sufficiently work-hardened to be suitable for manufacturing tools.[13] Bronze is an alloy of copper with tin; the latter of which being found in relatively few deposits globally delayed true tin bronze becoming widespread. During the Bronze Age, bronze was a major improvement over stone as a material for making tools, both because of its mechanical properties like strength and ductility and because it could be cast in molds to make intricately shaped objects. Bronze significantly advanced shipbuilding technology with better tools and bronze nails, which replaced the old method of attaching boards of the hull with cord woven through drilled holes.[14] The Iron Age is conventionally defined by the widespread manufacturing of weapons and tools using iron and steel rather than bronze.[15] Iron smelting is more difficult than tin and copper smelting because smelted iron requires hot-working and can be melted only in specially designed furnaces. The place and time for the discovery of iron smelting is not known, partly because of the difficulty of distinguishing metal extracted from nickel-containing ores from hot-worked meteoritic iron.[16]

During the growth of the ancient civilizations, many ancient technologies resulted from advances in manufacturing. Several of the six classic simple machines were invented in Mesopotamia.[17] Mesopotamians have been credited with the invention of the wheel. The wheel and axle mechanism first appeared with the potter's wheel, invented in Mesopotamia (modern Iraq) during the 5th millennium BC.[18] Egyptian paper made from papyrus, as well as pottery, were mass-produced and exported throughout the Mediterranean basin. Early construction techniques used by the Ancient Egyptians made use of bricks composed mainly of clay, sand, silt, and other minerals.[19]

Medieval and early modern[edit]

A stocking frame at Ruddington Framework Knitters' Museum in Ruddington, England

The Middle Ages witnessed new inventions, innovations in the ways of managing traditional means of production, and economic growth. Papermaking, a 2nd-century Chinese technology, was carried to the Middle East when a group of Chinese papermakers were captured in the 8th century.[20] Papermaking technology was spread to Europe by the Umayyad conquest of Hispania.[21] A paper mill was established in Sicily in the 12th century. In Europe the fiber to make pulp for making paper was obtained from linen and cotton rags. Lynn Townsend White Jr. credited the spinning wheel with increasing the supply of rags, which led to cheap paper, which was a factor in the development of printing.[22] Due to the casting of cannon, the blast furnace came into widespread use in France in the mid 15th century. The blast furnace had been used in China since the 4th century BC.[13] The stocking frame, which was invented in 1598, increased a knitter's number of knots per minute from 100 to 1000.[23]

First and Second Industrial Revolutions[edit]

Main articles: Industrial Revolution and Second Industrial Revolution

An 1835 illustration of a Roberts Loom weaving shed

The Industrial Revolution was the transition to new manufacturing processes in Europe and the United States from 1760 to the 1830s.[24] This transition included going from hand production methods to machines, new chemical manufacturing and iron production processes, the increasing use of steam power and water power, the development of machine tools and the rise of the mechanized factory system. The Industrial Revolution also led to an unprecedented rise in the rate of population growth. Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and capital invested. The textile industry was also the first to use modern production methods.[25]: 40 Rapid industrialization first began in Britain, starting with mechanized spinning in the 1780s,[26] with high rates of growth in steam power and iron production occurring after 1800. Mechanized textile production spread from Great Britain to continental Europe and the United States in the early 19th century, with important centres of textiles, iron and coal emerging in Belgium and the United States and later textiles in France.[25]

An economic recession occurred from the late 1830s to the early 1840s when the adoption of the Industrial Revolution's early innovations, such as mechanized spinning and weaving, slowed down and their markets matured. Innovations developed late in the period, such as the increasing adoption of locomotives, steamboats and steamships, hot blast iron smelting and new technologies, such as the electrical telegraph, were widely introduced in the 1840s and 1850s, were not powerful enough to drive high rates of growth. Rapid economic growth began to occur after 1870, springing from a new group of innovations in what has been called the Second Industrial Revolution. These innovations included new steel making processes, mass-production, assembly lines, electrical grid systems, the large-scale manufacture of machine tools and the use of increasingly advanced machinery in steam-powered factories.[25][27][28][29]

Building on improvements in vacuum pumps and materials research, incandescent light bulbs became practical for general use in the late 1870s. This invention had a profound effect on the workplace because factories could now have second and third shift workers.[30] Shoe production was mechanized during the mid 19th century.[31] Mass production of sewing machines and agricultural machinery such as reapers occurred in the mid to late 19th century.[32] The mass production of bicycles started in the 1880s.[32] Steam-powered factories became widespread, although the conversion from water power to steam occurred in England earlier than in the U.S.[33]

Modern manufacturing[edit]

Bell Aircraft's assembly plant in Wheatfield, New York in 1944

Electrification of factories, which had begun gradually in the 1890s after the introduction of the practical DC motor and the AC motor, was fastest between 1900 and 1930. This was aided by the establishment of electric utilities with central stations and the lowering of electricity prices from 1914 to 1917.[34] Electric motors allowed more flexibility in manufacturing and required less maintenance than line shafts and belts. Many factories witnessed a 30% increase in output owing to the increasing shift to electric motors. Electrification enabled modern mass production, and the biggest impact of early mass production was in the manufacturing of everyday items, such as at the Ball Brothers Glass Manufacturing Company, which electrified its mason jar plant in Muncie, Indiana, U.S. around 1900. The new automated process used glass blowing machines to replace 210 craftsman glass blowers and helpers. A small electric truck was now used to handle 150 dozen bottles at a time whereas previously used hand trucks could only carry 6 dozen bottles at a time. Electric mixers replaced men with shovels handling sand and other ingredients that were fed into the glass furnace. An electric overhead crane replaced 36 day laborers for moving heavy loads across the factory.[35]

Mass production was popularized in the late 1910s and 1920s by Henry Ford's Ford Motor Company,[32] which introduced electric motors to the then-well-known technique of chain or sequential production. Ford also bought or designed and built special purpose machine tools and fixtures such as multiple spindle drill presses that could drill every hole on one side of an engine block in one operation and a multiple head milling machine that could simultaneously machine 15 engine blocks held on a single fixture. All of these machine tools were arranged systematically in the production flow and some had special carriages for rolling heavy items into machining positions. Production of the Ford Model T used 32,000 machine tools.[36]

Lean manufacturing, also known as just-in-time manufacturing, was developed in Japan in the 1930s. It is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers.[37][38] It was introduced in Australia in the 1950s by the British Motor Corporation (Australia) at its Victoria Park plant in Sydney, from where the idea later migrated to Toyota.[39] News spread to western countries from Japan in 1977 in two English-language articles: one referred to the methodology as the "Ohno system", after Taiichi Ohno, who was instrumental in its development within Toyota.[40] The other article, by Toyota authors in an international journal, provided additional details.[41] Finally, those and other publicity were translated into implementations, beginning in 1980 and then quickly multiplying throughout the industry in the United States and other countries.[42]

Manufacturing strategy[edit]

According to a "traditional" view of manufacturing strategy, there are five key dimensions along which the performance of manufacturing can be assessed: cost, quality, dependability, flexibility and innovation.[43]

In regard to manufacturing performance, Wickham Skinner, who has been called "the father of manufacturing strategy",[44] adopted the concept of "focus",[45] with an implication that a business cannot perform at the highest level along all five dimensions and must therefore select one or two competitive priorities. This view led to the theory of "trade offs" in manufacturing strategy.[46] Similarly, Elizabeth Haas wrote in 1987 about the delivery of value in manufacturing for customers in terms of "lower prices, greater service responsiveness or higher quality".[47] The theory of "trade offs" has subsequently being debated and questioned,[46] but Skinner wrote in 1992 that at that time "enthusiasm for the concepts of 'manufacturing strategy' [had] been higher", noting that in academic papers, executive courses and case studies, levels of interest were "bursting out all over".[48]

Manufacturing writer Terry Hill has commented that manufacturing is often seen as a less "strategic" business activity than functions such as marketing and finance, and that manufacturing managers have "come late" to business strategy-making discussions, where, as a result, they make only a reactive contribution.[49][50]

Industrial policy[edit]

Main article: Industrial policy

Economics of manufacturing[edit]

Emerging technologies have offered new growth methods in advanced manufacturing employment opportunities, for example in the Manufacturing Belt in the United States. Manufacturing provides important material support for national infrastructure and also for national defense.

On the other hand, most manufacturing processes may involve significant social and environmental costs. The clean-up costs of hazardous waste, for example, may outweigh the benefits of a product that creates it. Hazardous materials may expose workers to health risks. These costs are now well known and there is effort to address them by improving efficiency, reducing waste, using industrial symbiosis, and eliminating harmful chemicals.

The negative costs of manufacturing can also be addressed legally. Developed countries regulate manufacturing activity with labor laws and environmental laws. Across the globe, manufacturers can be subject to regulations and pollution taxes to offset the environmental costs of manufacturing activities. Labor unions and craft guilds have played a historic role in the negotiation of worker rights and wages. Environment laws and labor protections that are available in developed nations may not be available in the third world. Tort law and product liability impose additional costs on manufacturing. These are significant dynamics in the ongoing process, occurring over the last few decades, of manufacture-based industries relocating operations to "developing-world" economies where the costs of production are significantly lower than in "developed-world" economies.[51]

Finance[edit]

From a financial perspective, the goal of the manufacturing industry is mainly to achieve cost benefits per unit produced, which in turn leads to cost reductions in product prices for the market towards end customers.[52][unreliable source?] This relative cost reduction towards the market, is how manufacturing firms secure their profit margins.[53]

Safety[edit]

Manufacturing has unique health and safety challenges and has been recognized by the National Institute for Occupational Safety and Health (NIOSH) as a priority industry sector in the National Occupational Research Agenda (NORA) to identify and provide intervention strategies regarding occupational health and safety issues.[54][55][56]

Manufacturing and investment[edit]

Capacity use in manufacturing in Germany and the United States

Surveys and analyses of trends and issues in manufacturing and investment around the world focus on such things as:

In addition to general overviews, researchers have examined the features and factors affecting particular key aspects of manufacturing development. They have compared production and investment in a range of Western and non-Western countries and presented case studies of growth and performance in important individual industries and market-economic sectors.[57][58]

On June 26, 2009, Jeff Immelt, the CEO of General Electric, called for the United States to increase its manufacturing base employment to 20% of the workforce, commenting that the U.S. has outsourced too much in some areas and can no longer rely on the financial sector and consumer spending to drive demand.[59] Further, while U.S. manufacturing performs well compared to the rest of the U.S. economy, research shows that it performs poorly compared to manufacturing in other high-wage countries.[60] A total of 3.2 million – one in six U.S. manufacturing jobs – have disappeared between 2000 and 2007.[61] In the UK, EEF the manufacturers organisation has led calls for the UK economy to be rebalanced to rely less on financial services and has actively promoted the manufacturing agenda.

Major manufacturing nations[edit]

See also: Outline of manufacturing § By country

According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States of America, Japan, Germany, and India.[62][63]

UNIDO also publishes a Competitive Industrial Performance (CIP) Index, which measures the competitive manufacturing ability of different nations. The CIP Index combines a nation's gross manufacturing output with other factors like high-tech capability and the nation's impact on the world economy. Germany topped the 2020 CIP Index, followed by China, South Korea, the United States, and Japan.[64][65]

List of countries by manufacturing output[edit]

These are the top 50 countries by total value of manufacturing output in U.S. dollars for its noted year according to World Bank:[66]

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

See also[edit]

References[edit]

Further reading[edit]

External links[edit]

Look up manufacturing in Wiktionary, the free dictionary.

Wikimedia Commons has media related to Manufacturing.

Wikiquote has quotations related to Manufacturing.

38 languages

Tools

Appearance hide

Text

Width

Color (beta)

Coordinates: 33°26′16″N 86°59′51″W

From Wikipedia, the free encyclopedia

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hueytown is a city in western Jefferson County, Alabama, United States. It is part of the Birmingham metropolitan area, and was part of the heavy industry development in this area in the 20th century. The population was 16,776 at the 2020 census.[4]

Hueytown was the home of the Alabama Gang, famous in NASCAR stock car racing. In 1992 the city became known for the unexplained "Hueytown Hum", a mysterious noise later thought to be caused by large underground ventilation fans used in a nearby coal mine.

Its nearby residential and business communities were damaged by an F5 tornado on April 8, 1998 and by an EF4 tornado on April 27, 2011.

Geography[edit]

This city is located at 33°26′16″N 86°59′51″W (33.437709, -86.997579).[6]

According to the United States Census Bureau, the city has a total area of 20.145 square miles (52.18 km2), of which 19.979 square miles (51.75 km2) is land and 0.166 square miles (0.43 km2), is water.[2]

It is accessible from I-20/59 exits 112 and 115.

Demographics[edit]

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

2020 census[edit]

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

As of the 2020 census, there were 16,776 people, 6,545 households, and 4,553 families residing in the city.[9] The population density was 852.7 inhabitants per square mile (329.2/km2) There were 7,128 housing units.

2010 census[edit]

As of the 2010 census, there were 16,105 people, 6,412 households, and 4,517 families residing in the city. The population density was 1,388.4 inhabitants per square mile (536.1/km2). There were 6,998 housing units at an average density of 603.3 per square mile (232.9/km2). The racial makeup of the city was 70.0% White, 27.2% Black or African American, 0.3% Native American, 0.5% Asian, 1.1% from other races, and 1.0% from two or more races. 2.0% of the population were Hispanic or Latino of any race.

There were 6,412 households, out of which 27.5% had children under the age of 18 living with them, 50.4% were married couples living together, 15.7% had a female householder with no husband present, and 29.6% were non-families. 26.4% of all households were made up of individuals, and 11.3% had someone living alone who was 65 years of age or older. The average household size was 2.49 and the average family size was 2.99.

In the city, the population was spread out, with 22.3% under the age of 18, 7.8% from 18 to 24, 26.0% from 25 to 44, 27.4% from 45 to 64, and 16.5% who were 65 years of age or older. The median age was 40 years. For every 100 females, there were 89.5 males. For every 100 females age 18 and over, there were 92.2 males.

2000 census[edit]

As of the 2000 census, there were 15,364 people, 6,155 households, and 4,517 families residing in the city. The population density was 1,323.7 inhabitants per square mile (511.1/km2). There were 6,519 housing units at an average density of 561.7 per square mile (216.9/km2). The racial makeup of the city was 83.81% White, 15.49% Black or African American, 0.14% Native American, 0.13% Asian, 0.08% from other races, and 0.34% from two or more races. 0.47% of the population were Hispanic or Latino of any race.

There were 6,155 households, out of which 29.5% had children under the age of 18 living with them, 57.8% were married couples living together, 12.3% had a female householder with no husband present, and 26.6% were non-families. 23.9% of all households were made up of individuals, and 10.9% had someone living alone who was 65 years of age or older. The average household size was 2.47 and the average family size was 2.92.

In the city, the population was spread out, with 22.2% under the age of 18, 8.6% from 18 to 24, 27.6% from 25 to 44, 24.4% from 45 to 64, and 17.2% who were 65 years of age or older. The median age was 39 years. For every 100 females, there were 90.2 males. For every 100 females age 18 and over, there were 86.4 males.

Economy[edit]

The median income for a household in the city was $41,225, and the median income for a family was $49,380. Males had a median income of $36,087 versus $26,025 for females. The per capita income for the city was $19,735. About 5.3% of families and 6.8% of the population were below the poverty line, including 5.2% of those under age 18 and 9.2% of those age 65 or over.

Industrial history[edit]

Although the Hueytown area has a history of farming, it has been a part of both the steel and coal mining industries in Jefferson County.

William & Joseph Woodward formed The Woodward Iron Company on New Year's Eve, 1881. With William as company president and Joseph as company secretary, the brothers purchased the plantation of Fleming Jordan. The plantation had originally been developed by his father, Mortimer Jordan, in 1828. The plantation included portions of present-day Hueytown and was one of the largest cotton plantations in the area.

On the former site of Mrs. Jordan's rose garden, Woodward Furnace No. 1 began operation on August 17, 1883. A second furnace went into blast in January 1887 and the two furnaces had a daily output of 165 tons. A mine also went into operation in the Dolomite community, which is today mostly within the City of Hueytown. By 1909, there was a third furnace and a daily capacity of 250,000 tons with a workforce of 2000 men on the payroll.

By the 1920s Woodward Iron's many expansions made it one of the nation's largest suppliers of pig iron. Joseph's son, A. H. (Rick) Woodward, had become Chairman of the Board of Woodward Iron, and was one of the most prominent citizens of Alabama. He is probably best remembered as the owner of the Birmingham Barons minor league baseball team and the namesake of Rickwood Field, the nation's oldest professional baseball park still in use.

In 1968, Mead Corporation acquired Woodward Iron just as the steel industry was going into decline. In 1973, the last blast furnace closed, and Koppers Corporation bought the remaining coke production plant. Eventually, even Koppers had closed coke production as well. Much of the 1,200-acre (490 ha) site today has been re-developed for lighter industrial use.[10]

Coal mining began about the start of the 20th century at Virginia Mines. Today this section of Hueytown contains mostly subdivisions of homes (Virginia Estates and Edenwood). However, some of the original buildings from its mining past remain, including the superintendent's house, multiple supervisors' houses, and two company-built churches.

Some source[who?] say veteran prospector Truman H. Aldrich assembled these lands as part of his extensive coal properties, others cite two red-headed brothers, George and E. T. Shuler, as having opened the Virginia Mine in 1902. Having recently arrived from Virginia City, Nevada, they named their new mine after that western city. A mine disaster in February 1905 caused extensive damage. An underground explosion, one of the worst recorded mining disasters in Alabama history, entombed the entire day crew and caved in the mine entrance. When rescuers finally cleared the 1500-foot-deep (150 m) shaft, they found 106 men dead and 20 dead mules.

In 1936, Republic Steel purchased the mine. It continued to be worked until September 1953, when it closed permanently.[11]

Government[edit]

The City of Hueytown was incorporated on December 3, 1959, and operates under a Mayor-Council form of government. The Mayor is elected to a four-year term. The five City Council members are also elected to four-year terms. Originally elected at-large, the city changed to single-member districts in the 1990s which resulted in the creation of one majority-minority council district. Neither position is term-limited.[12]

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mayor C.C. "Bud" Newell died in office. The President of the City Council, Gerald Hicks, was then elevated to the position of Mayor and completed the remaining years of the term.

The original Alderman for the City of Hueytown in 1960 were as follows:[13]

Listed below is a partial list (alphabetical) of former members of The City Council who were not otherwise members of the original Council.

Schools and education history[edit]

The Hueytown area has been served by many schools over the past one hundred years. Most of these have been public schools of The Jefferson County School System which was founded in 1898. However, the first established school in the community was in August 1874, when several families gathered to build a small log building that served as both a church and school. That structure was located on the hill behind present-day Pleasant Ridge Baptist Church. A later grammar school was built on Upper Wickstead Road but burned down in 1907. The following year, Hueytown Grammar School opened with just four teachers for its 100 students. Also located across the street from Pleasant Ridge Baptist Church it faced Dabbs Avenue. The school was replaced with a larger building in 1935 which faced Hueytown Road. That entire structure burned to the ground on the night of March 3, 1949. The present Hueytown Elementary School, which has been expanded many times, first opened in the fall of 1950.

The present Hueytown Intermediate School opened to the students in the fall of 2020. (November 2 or 9)

Other schools serving the city include: Hueytown High School, Hueytown Middle School (formerly Pittman Middle School and Pittman Junior High), Concord Elementary School and North Highland Elementary School. Four private religious schools, Deeper Life Academy, Garywood Christian School, Brooklane Baptist Academy, and Rock Creek Academy are located in Hueytown.

Other schools that served Hueytown in years past have long since been closed. They included Virginia Mines School, Rosa Zinnerman Elementary, and Bell High School. When an F5 tornado destroyed Oak Grove High School and Oak Grove Elementary School on April 8, 1998, students from the Oak Grove high school grades were temporarily relocated to the former Bell School campus until their new school reopened two years later.

Recently the Hueytown High School Marching, Symphonic, and Jazz Bands have gained some prestige by playing at the Alabama Music Educators Association (AMEA) and a dual concert with the University of Alabama at Birmingham's Symphonic and Wind ensembles.

Sports and recreation[edit]

The abbreviation HYT (HueYTown) has become a popular term of reference for Hueytown among some of the residents; it is constantly used for sports. (for example HYT football).

Hueytown High School's football team made it to the Alabama State Playoffs in 1974, 1975, 1995, and 2004. They also made the playoffs in 2006, 2007, and 2008, marking the first time in school history to make three straight appearances. The 2010 team set a school record for wins by going 11–2, but the record was broken the next year by Jameis Winston and company by going 13–1. On June 18, 2009 Hueytown High School's football Coach Jeff Smith resigned. Spain Park High School assistant coach Matt Scott became the new head coach on July 7, 2009. The team made the playoffs once again in the 2010 and 2011 season under Coach Scott. Hueytown also made it to the 2016 state playoffs under Coach Scott Mansell, who was in his third year as head coach.

HHS's softball team has won the Alabama State Softball championship three times in four years: 2005 and 2006 as a 5A school and 2008 as a 6A school under Coach Lissa Walker. They won again in 2011 as a 5A school. After the 2011 season, Coach Walker resigned and was hired as the new coach for the Vestavia softball team. Coach Christie McGuirk was hired in Coach Walker's place to be the new coach for the 2011 season.

In 1974, the Hueytown High School Wrestling Team won the 4A State Championship under the guidance of then head-wrestling coach, Tony Morton.[14]

Hueytown High School implemented its soccer program in the spring of 2014.

In addition to the public school sports programs, Hueytown offers many other community sports programs. For decades the city has enjoyed a very strong Dixie Youth Baseball program for all eligible age groups. Its Dixie Youth teams use facilities at Hueytown's Bud Newell Park and have seen several of its players eventually make it to the Major Leagues. The city also has a very strong girls fastpitch program that is based at Allison-Bonnett Girls Softball Park, also a city facility. Its Angels league All-Star team won the Dixie World Series championship in the summer of 2003 and its 6U All-Stars won the Alabama State Championship in the summer of 2009. Hueytown also has a Swim Club and a youth football program.

Hueytown also has Youth Soccer which started in 2003.

Hueytown is also home to the Central Alabama Boys & Girls Club, a multimillion-dollar facility that provides a variety of sports and recreation opportunities for the youth of the area, focusing primarily on after school and summer programs. It routinely serves more than 300 children each day.

The Alabama Gang[edit]

Hueytown was home to one of the dominant racing groups in NASCAR, the Alabama Gang. The city's main thoroughfare, Allison-Bonnett Memorial Drive, takes its name from drivers Bobby Allison, Donnie Allison, Davey Allison, Clifford Allison, and Neil Bonnett. The Alabama Gang also includes racing legend Charles "Red" Farmer. Though not considered a member of The Alabama Gang, Bobby and Donnie's older brother Eddie Allison had an active role in NASCAR for many years as a respected engine builder and still resides in Hueytown. His son, Jacob, is a radio personality on Birmingham, Alabama station WJOX. He also resides in Hueytown.

Because of its established motorsports roots, Hueytown was chosen as BMW Motorsport's initial North American base of operations before its first season with the International Motor Sports Association (IMSA) in 1975.

Hueytown Hum[edit]

Beginning in late 1991 residents of Hueytown, and other nearby communities, reported hearing a droning low frequency hum at irregular intervals.[15] The bizarre noises momentarily gained national attention and were reported in the New York Times in April 1992. In a logical conclusion town officials and many residents suspected the source of the hum was a massive $7 million mine ventilation fan with blades 26 feet (7.9 m) in diameter.[16] From local reports and an informal investigation by ABC World News Tonight, the fan operated by Jim Walter Resources was generally thought to be the culprit. However, JWR (then owned by a subsidiary of KKR) was in bankruptcy proceedings and denied its fan was the source. Following an inconclusive series of studies the hum subsided later in the year, never to return.[17]

Notable people[edit]

References[edit]

External links[edit]

|

|

|

|

Discover the precision and durability of Eberle Carbide Band Saw Blades, designed for cutting tough materials with ease. Enhance productivity with our expert insights on features, benefits, and maintenance tips. Eberle Carbide Band Saw Blades are a staple in the world of industrial cutting. Known for their precision and durability, these blades are designed to handle the toughest materials with ease. Whether you're cutting through metal, wood, or composite materials, Eberle blades offer a reliable solution. Their advanced design and high-quality materials ensure that each cut is clean and efficient. For professionals in the industry, choosing the right band saw blade is crucial. Eberle provides a range of options tailored to specific needs, ensuring optimal performance. Understanding the features and benefits of these blades can significantly enhance productivity and reduce downtime. With proper maintenance and the right choice of blade, you can extend the life of your equipment and achieve superior results. This post delves into the key aspects of Eberle Carbide Band Saw Blades, offering insights into their features, benefits, and maintenance tips to help you make informed decisions.

Eberle Carbide Band Saw Blades are engineered for precision and longevity. One of their standout features is the use of high-quality carbide tips. These tips are designed to withstand high temperatures and resist wear, making them ideal for cutting hard materials. The blades also feature a unique tooth geometry that enhances cutting efficiency. This design ensures that each tooth makes optimal contact with the material, reducing friction and heat buildup. Another key feature is the blade's flexibility. Eberle blades are crafted to maintain their shape under stress, which minimizes the risk of breakage. This flexibility is crucial when working with materials that require intricate cuts or when operating at high speeds. The blades are also available in various widths and thicknesses, allowing users to select the best option for their specific application. Eberle's commitment to quality is evident in their manufacturing process. Each blade undergoes rigorous testing to ensure it meets the highest standards. This attention to detail results in a product that delivers consistent performance and reliability. For professionals seeking a dependable cutting solution, Eberle Carbide Band Saw Blades offer a combination of durability, precision, and versatility.

Carbide band saw blades offer numerous advantages in industrial settings. One of the primary benefits is their ability to cut through tough materials with ease. The carbide tips are incredibly hard, allowing them to maintain sharpness longer than traditional steel blades. This means less frequent blade changes and reduced downtime.

Eberle blades stand out in the realm of precision cutting solutions. Their design and construction offer several advantages over other options. One of the key differentiators is the use of high-quality carbide tips. These tips provide superior hardness and wear resistance, ensuring long-lasting performance even in demanding applications. Compared to traditional steel blades, Eberle blades maintain their sharpness for a longer period. This reduces the frequency of blade changes and minimizes downtime, leading to increased productivity. The unique tooth geometry of Eberle blades also enhances cutting efficiency, allowing for faster and cleaner cuts. In terms of versatility, Eberle blades are suitable for a wide range of materials. Whether cutting metals, wood, or composites, these blades deliver consistent results. This adaptability makes them a preferred choice for industries that require precision and reliability. Eberle's commitment to quality is evident in their manufacturing process. Each blade undergoes stringent testing to ensure it meets the highest standards. This attention to detail results in a product that outperforms many other cutting solutions on the market. For professionals seeking a reliable and efficient cutting tool, Eberle blades offer a compelling option.

Proper maintenance is crucial for extending the life of carbide band saw blades. One of the most important steps is regular cleaning. After each use, remove any debris or buildup from the blade. This prevents material from hardening on the surface, which can lead to increased friction and wear. Another key maintenance tip is to ensure proper tensioning. A blade that is too loose or too tight can cause uneven wear and reduce cutting efficiency. Regularly check the tension and adjust as needed to maintain optimal performance. Lubrication is also essential. Applying a suitable lubricant can reduce friction and heat buildup, which helps preserve the blade's sharpness. Be sure to use a lubricant that is compatible with the materials being cut. Inspecting the blade for damage is another important step. Look for signs of wear, such as chipped teeth or cracks. If any damage is detected, replace the blade immediately to prevent further issues. Finally, store the blades properly when not in use. Keep them in a dry, cool place to prevent rust and corrosion. By following these maintenance tips, you can significantly extend the life of your carbide band saw blades and ensure consistent performance.

Selecting the right band saw blade for specific materials is crucial for achieving optimal results. The first consideration is the material's hardness. For hard materials like metal, a carbide-tipped blade is recommended due to its superior durability and cutting efficiency. The thickness of the material is another important factor. Thicker materials require a blade with a larger tooth pitch to ensure efficient cutting. Conversely, thinner materials benefit from a finer tooth pitch to prevent tearing or chipping. The type of cut also influences blade selection. For straight cuts, a standard blade may suffice. However, for intricate or curved cuts, a more flexible blade is necessary to navigate the contours without breaking. Material composition should also be considered. For example, cutting wood requires a different blade than cutting metal or composites. Each material has unique properties that affect the cutting process, so choosing a blade specifically designed for that material is essential. Eberle band saw blades Finally, consider the speed and feed rate of the cutting operation. Some blades are designed to operate at higher speeds, which can enhance productivity. Precision cutting blades By carefully evaluating these factors, you can select the right band saw blade for your specific application and achieve superior results.

Band saw blade performance can be affected by several common issues. One frequent problem is blade drift, where the blade veers off course during cutting. Band saw blade suppliers This can be caused by improper tensioning or misalignment of the blade guides. To address this, ensure the blade is properly tensioned and the guides are correctly aligned. Another issue is premature wear or breakage. This can result from using the wrong blade for the material or operating at incorrect speeds. To prevent this, choose a blade suited for the material and adjust the speed and feed rate accordingly. Poor cutting quality is another concern. This can manifest as rough or uneven cuts. Often, this is due to a dull blade or incorrect tooth pitch. Regularly inspect the blade for sharpness and replace it if necessary. Additionally, ensure the tooth pitch matches the material being cut. Excessive noise or vibration during operation can indicate a problem. This may be caused by a loose blade or worn bearings. Check the blade tension and inspect the machine components for wear. By understanding these common issues and implementing appropriate troubleshooting measures, you can maintain optimal band saw blade performance and achieve consistent cutting results.

Tooth geometry plays a crucial role in cutting efficiency. The shape and arrangement of the teeth on a band saw blade determine how effectively it can cut through material. One key aspect of tooth geometry is the rake angle. A positive rake angle allows for more aggressive cutting, which is beneficial for softer materials. Conversely, a negative rake angle provides a more controlled cut, ideal for harder materials. The tooth pitch, or the distance between teeth, also affects cutting performance. A larger tooth pitch is suitable for thicker materials, as it allows for efficient chip removal. A finer tooth pitch is better for thinner materials, as it reduces the risk of tearing or chipping. Tooth set, or the side-to-side bending of the teeth, influences the width of the cut. A wider set is useful for cutting softer materials, while a narrower set is better for harder materials. The gullet, or the space between teeth, is another important factor. A larger gullet can accommodate more material, which is beneficial for faster cutting. By understanding and optimizing tooth geometry, you can enhance cutting efficiency and achieve superior results with your band saw blades.

Carbide technology has seen significant innovations in recent years, enhancing its application in industrial cutting. One of the key advancements is the development of micro-grain carbide. This material offers superior hardness and wear resistance, resulting in longer-lasting blades that maintain their sharpness over extended periods. Another innovation is the use of advanced coatings. These coatings reduce friction and heat buildup, which can prolong the life of the blade and improve cutting efficiency. Coatings also provide additional protection against corrosion and wear, making them ideal for demanding applications. The integration of computer-aided design (CAD) in blade manufacturing has also revolutionized carbide technology. CAD allows for precise control over tooth geometry, resulting in blades that are optimized for specific cutting tasks. This precision enhances cutting performance and reduces material waste. Additionally, advancements in manufacturing processes have led to more consistent and reliable carbide blades. Improved quality control measures ensure that each blade meets the highest standards, providing users with a dependable cutting solution. These innovations in carbide technology continue to push the boundaries of what is possible in industrial cutting, offering professionals enhanced performance and efficiency in their operations.

Optimizing cutting speed and feed rates with Eberle blades is essential for maximizing performance. The first step is to understand the material being cut. Different materials require different speeds and feed rates to achieve optimal results. For example, harder materials like metal may require slower speeds and lower feed rates to prevent excessive wear on the blade. The blade's tooth geometry also plays a role in determining the appropriate speed and feed rate. Blades with a positive rake angle can handle higher speeds, while those with a negative rake angle may require slower speeds for controlled cutting. Monitoring the cutting process is crucial. Pay attention to the quality of the cut and adjust the speed and feed rate as needed.

Safety is paramount when using industrial band saw blades. One of the most important considerations is proper training. Ensure that all operators are trained in the safe use of band saws and understand the potential hazards associated with their operation. Personal protective equipment (PPE) is essential. Operators should wear safety goggles, gloves, and hearing protection to minimize the risk of injury. Loose clothing and jewelry should be avoided, as they can become entangled in the machinery. Regular maintenance of the band saw is crucial for safety. Inspect the machine for any signs of wear or damage and address any issues promptly. Proper tensioning and alignment of the blade are also important to prevent accidents. Ensure that the work area is clean and free of obstructions. A cluttered workspace can increase the risk of accidents and make it difficult to operate the band saw safely. Finally, always follow the manufacturer's guidelines for safe operation. This includes using the appropriate blade for the material and adhering to recommended speed and feed rates. By prioritizing safety, you can reduce the risk of accidents and ensure a safe working environment when using industrial band saw blades.

Eberle Carbide Band Saw Blades offer a reliable solution for industrial cutting needs. Their precision and durability make them a preferred choice for professionals. Understanding the key features and benefits of these blades can enhance productivity and reduce downtime. Proper maintenance and blade selection are crucial for achieving optimal results. By addressing common issues and optimizing cutting parameters, you can ensure consistent performance. Safety should always be a priority when using band saw blades. With the right approach, Eberle blades can deliver superior cutting efficiency and reliability. Investing in quality blades is a smart choice for any industrial application.

Discover the superior performance of carbide-tipped band saw blades. Ideal for cutting tough materials, these blades offer durability, precision, and cost-effectiveness in industrial settings. Wear-resistant saw blades Learn about their advantages, applications, and maintenance tips, plus innovations from Eberle to enhance your cutting efficiency. "Carbide-tipped band saw blades are a game-changer in the world of cutting tools. They offer superior performance and longevity compared to traditional blades. Carbide blade technology These blades are designed to handle the toughest materials with ease, making them a favorite in industrial settings. Their unique construction combines the strength of carbide with the flexibility of a steel body, resulting in a tool that can withstand high-speed cutting and resist wear. This makes them ideal for applications where precision and durability are paramount. Whether you're cutting metal, wood, or composite materials, carbide-tipped blades deliver clean, accurate cuts every time.

Carbide-tipped band saw blades offer numerous advantages. Their primary benefit is durability. The carbide tips are incredibly hard, allowing them to maintain sharpness longer than traditional blades. This means fewer blade changes and less downtime. They also provide superior cutting performance. The sharpness of carbide tips ensures clean, precise cuts, reducing the need for secondary finishing processes. This is particularly beneficial in industrial settings where time and precision are critical. Additionally, these blades can cut through a wide range of materials, from hard metals to abrasive composites. This versatility makes them a valuable tool in any workshop. Another advantage is their resistance to heat. Carbide-tipped blades can operate at higher speeds without losing their edge, making them ideal for high-volume production environments. Finally, their longevity and performance can lead to cost savings over time, as they require less frequent replacement and maintenance.

Carbide-tipped blades stand out when compared to traditional steel blades. The most significant difference is in their composition. Carbide-tipped blades have a steel body with carbide teeth, while traditional blades are typically made entirely of steel. This difference in materials results in varying performance characteristics. Carbide-tipped blades are harder and more wear-resistant, allowing them to maintain sharpness longer. This leads to cleaner cuts and less frequent blade changes. In contrast, traditional steel blades tend to dull more quickly, requiring more frequent maintenance. Additionally, carbide-tipped blades can handle a wider range of materials, including hard metals and composites, whereas steel blades may struggle with these tougher materials. The heat resistance of carbide-tipped blades also allows for faster cutting speeds, increasing productivity. While carbide-tipped blades may have a higher initial cost, their longevity and performance often result in cost savings over time compared to traditional steel blades.

In industrial settings, carbide-tipped band saw blades are invaluable. Their ability to cut through tough materials makes them ideal for metalworking industries. They can handle everything from stainless steel to titanium, providing clean, precise cuts. This precision is crucial in industries where accuracy is paramount, such as aerospace and automotive manufacturing. Additionally, these blades are used in woodworking, particularly for cutting hardwoods and composites. Their sharpness and durability ensure smooth cuts, reducing the need for additional finishing. In the construction industry, carbide-tipped blades are used for cutting concrete and other abrasive materials. Their heat resistance allows them to operate at high speeds, increasing efficiency in high-volume production environments. Furthermore, their versatility makes them suitable for custom fabrication shops, where a variety of materials may need to be cut. Overall, the applications of carbide-tipped band saw blades in industrial settings are vast, making them a crucial tool for many industries.

Proper maintenance is key to extending the life of carbide-tipped saw blades. Regular cleaning is essential. Remove any debris or buildup from the blade after each use to prevent damage. Inspect the blade regularly for signs of wear or damage. Look for chipped or dull teeth, and replace the blade if necessary. Proper tensioning is also crucial. Ensure the blade is tensioned correctly according to the manufacturer's specifications to prevent unnecessary stress and wear. Lubrication is another important factor. Use a suitable lubricant to reduce friction and heat buildup during cutting. This will help maintain the blade's sharpness and prevent overheating. Additionally, avoid cutting materials that exceed the blade's capabilities, as this can cause damage. Store blades properly when not in use. Keep them in a dry, clean environment to prevent rust and corrosion. By following these maintenance tips, you can significantly extend the life of your carbide-tipped saw blades.

Choosing the right band saw blade is crucial for optimal performance. Start by considering the material you need to cut. Different materials require different blade types. For hard metals, a carbide-tipped blade is ideal due to its durability and sharpness. For softer materials like wood, a standard steel blade may suffice. Next, consider the thickness of the material. Thicker materials require blades with larger teeth for efficient cutting. The type of cut you need is also important. For straight cuts, a blade with fewer teeth per inch is suitable, while for intricate cuts, a finer-toothed blade is better. Additionally, consider the speed and power of your band saw. Ensure the blade you choose is compatible with your machine's specifications. Finally, consider the cost. While carbide-tipped blades may have a higher upfront cost, their longevity and performance can lead to cost savings over time. By considering these factors, you can choose the right band saw blade for your needs.

Precision plays a critical role in the performance of carbide-tipped band saw blades. These blades are designed for accuracy, providing clean, precise cuts. This precision is achieved through the sharpness of the carbide tips, which maintain their edge longer than traditional blades. The precise cutting ability of these blades reduces the need for secondary finishing processes, saving time and resources. In industries where accuracy is paramount, such as aerospace and automotive manufacturing, the precision of carbide-tipped blades is invaluable. They ensure that components are cut to exact specifications, reducing waste and improving efficiency. Additionally, the precision of these blades allows for faster cutting speeds without sacrificing quality. This increases productivity in high-volume production environments. The role of precision in carbide-tipped band saw blade performance cannot be overstated. It is a key factor in their popularity and effectiveness across various industries, making them a preferred choice for professionals.